A Probe Station is a device used for electrical performance testing of semiconductor devices, integrated circuits, and other microelectronic components. It is widely applied in research and development, quality control, and production testing.

### Definition of Probe Station

A probe station is a critical piece of equipment for testing the electrical performance of semiconductor devices. It uses precise mechanical structures, high-performance probe tips, and electrical testing instruments to perform direct electrical tests on semiconductor chips, integrated circuits, and other microelectronic devices.

Probe stations are characterized by high precision, high sensitivity, and strong environmental adaptability. They support various testing methods, including integrated optical testing and electromagnetic testing, providing robust support for the comprehensive performance evaluation of semiconductor devices.

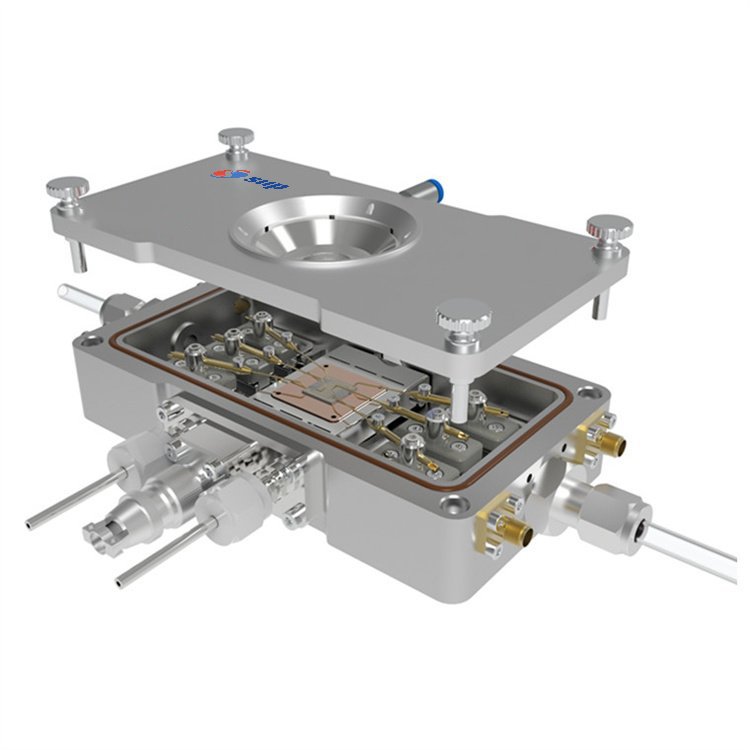

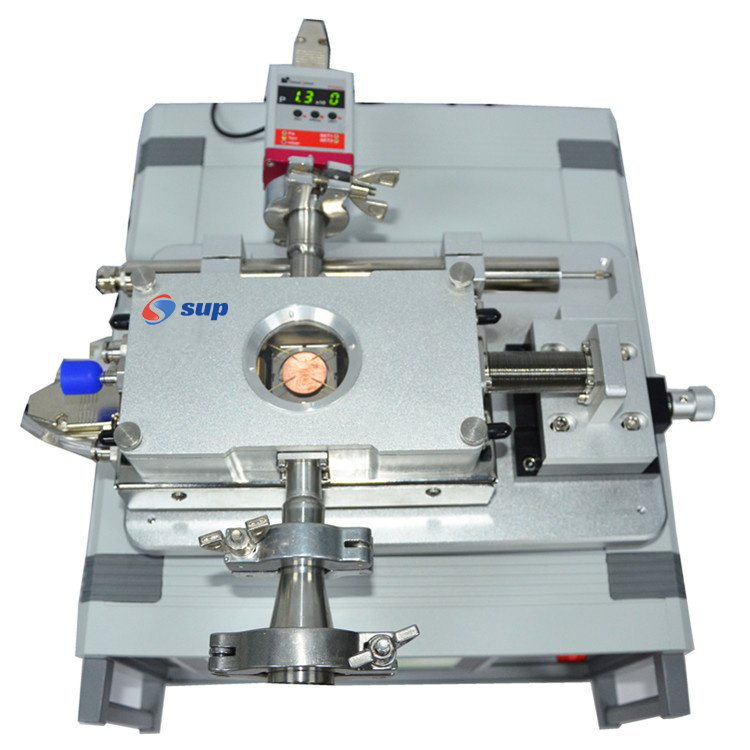

### Structure of a Probe Station

The probe station can be divided into different functional modules. Here are the main components:

- Probe Station Base: This is the foundational structure that provides a stable platform to support other components and typically includes fixtures for securing wafers or chips.

- Probe Card or Probe Holder: The probe card is a carrier with multiple tiny probes that make contact with the test points on the chip.

- Probe Head: This includes the probe arm and probe tips, which have a diameter so small that it can reach micrometer or even nanometer levels for direct contact with the chip's test points.

- Chuck (Sample Stage): This is a platform for placing and securing wafers, allowing adjustments in the X, Y, Z axes and rotation.

- Microscope System: This is used for alignment and visual inspection, helping the operator observe the contact between the probes and the chip, usually equipped with a high-resolution CCD camera.

- Control System: This includes micrometers and motion control systems for precisely adjusting the positions of the probes and samples, ensuring accurate contact with the specified locations on the chip.

- Electrical System (Source Meter): The source meter provides test signals and measures returning signals.

- Testing Software: The software control system automates the testing process, including wafer mapping, test program setup, and data collection and analysis.

- Others (if configured): Robotic arms, vacuum systems, temperature control systems, gas control systems, etc.

### Working Principle of a Probe Station

The probe station achieves accurate measurement and analysis of samples through its fine structural design and control systems:

1. Positioning: The sample stage accurately positions the item under test (wafer, chip, etc.).

2. Visual Assistance: Optical elements are used to magnify the observation, ensuring precise alignment of the probes with the measurement points.

3. Securing the Sample: The chuck secures the wafer or chip, possibly using fixtures or vacuum suction.

4. Probe Control: Electromagnetic or piezoelectric devices precisely control the movement and positioning of the probes on the sample surface.

5. Signal Collection: Built-in sensors record the signals generated from the interaction between the probes and the sample in real-time.

6. Data Processing: The collected signals are processed to analyze the morphology and performance information of the sample.

7. Automated Testing: Manual, semi-automated, or fully automated probe station systems complete the testing process.

### Application Scenarios of Probe Stations

- Electrical Performance Testing: Provides IV/CV characteristics, Hall effect, and other electrical performance tests for materials/devices.

- Optical Testing: Measures light intensity/wavelength for LD/LED/PD, assessing the photoelectric conversion efficiency and stability of optoelectronic materials.

- Failure Analysis: Analyzes failure in electronic devices like RF characteristics to help locate faults for in-depth analysis.

- Internal Circuit Testing: Tests internal circuits/electrodes/PADs of chips, enabling precise extraction of signals from tiny connection points for further testing and analysis.

- Reliability Analysis: Validates the reliability of materials to ensure stability and durability under various conditions.

- Micro-nano Scale Manipulation: Conducts localized measurements of electrical properties such as conductivity, resistance, and capacitance at the nanoscale.

- Microscopic Observation: When combined with SEM (Scanning Electron Microscope) or TEM (Transmission Electron Microscope), the probe station can provide multi-scale material characterization from macro to nanoscale.

- Automated Testing: Integrates automated wafer handling systems, including wafer transport, positioning, and identification systems, to improve testing efficiency and reduce human errors.

- Special Environment Testing: Can test chips under different temperatures, pressures, or special gas environments.

### Fields of Application for Probe Stations

- Semiconductor Industry: Conducts electrical performance testing for integrated circuits, including wafer testing and post-packaging testing.

- Optoelectronic Industry: Tests the performance of optoelectronic components such as LEDs, photodetectors, and lasers, focusing on precision electrical measurements.

- Materials Science: Used to characterize the microstructure of material surfaces, such as surface defects and grain sizes, supporting material research.

- Microelectronics: Performs precision electrical measurements for complex, high-speed devices, reliability verification, and failure analysis to ensure quality and reliability.

- Nanotechnology: Involves the preparation, characterization, and performance testing of nanomaterials and nanostructures, and the manufacture and testing of nano-devices.

- Biomedical: Studies the biocompatibility of biological materials' surfaces, and provides high-resolution imaging and analysis of biomolecules, cells, and tissues.

- Research and Education: Used in research institutions and universities for scientific research and teaching, supporting both fundamental and applied research.

- Other Fields: Includes applications in the energy sector, aerospace, automotive electronics, communication technology, quantum computing and information, and sensor technology.

Contact: Bruce Liu

WhatsApp: +86-18059149998

Tel: +86-18059149998

Email: sales@supsemi.com

Add: Room 1402, Building 1, No. 89 Xibeilu, Xishancun, Xibei Street, Xinluo District, Longyan City, Fujian Province

We chat