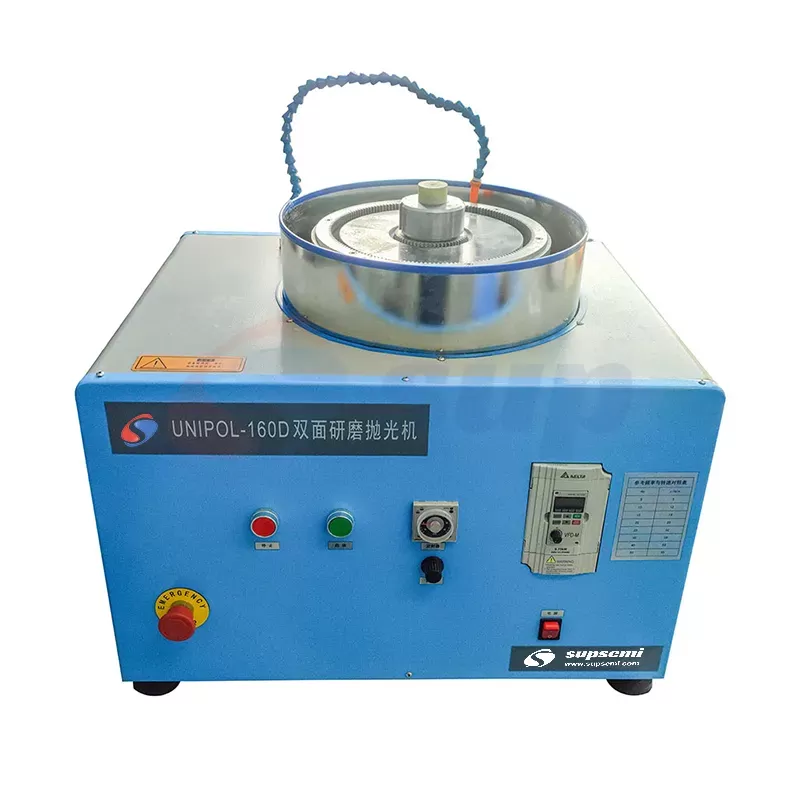

Product Model: UNIPOL-160D

Product Description: The UNIPOL-160D Double-Sided Lapping and Polishing Machine is primarily designed for the double-sided precision lapping and polishing of sheet materials such as quartz wafers, sapphire, ceramics, glass, infrared optical materials (e.g., crystals like Zinc Selenide, Zinc Sulfide, Silicon, Germanium), and metals.

Product Description

The UNIPOL-160D Double-Sided Lapping and Polishing Machine is primarily designed for the double-sided precision lapping and polishing of sheet materials such as quartz wafers, sapphire, ceramics, glass, infrared optical materials (e.g., crystals like Zinc Selenide, Zinc Sulfide, Silicon, Germanium), and metals.

This machine employs a worm gear reducer as its transmission mechanism. Through a gear set, it achieves rotational motion of the upper, middle, and lower spindles at different speeds and in different directions. This configuration generates a speed differential and relative motion between the upper and lower lapping/polishing plates and the intermediate sun gear. Samples are placed within the inner holes of the carrier planetary gears, which are driven by the sun gear, thus enabling double-sided lapping and polishing.

The UNIPOL-160D Double-Sided Lapping and Polishing Machine offers versatile processing capabilities. It can be operated using lapping plates with abrasive slurry for sample lapping, or alternatively, it can utilize a polishing plate with sandpaper for sample grinding. When using sandpaper, the process involves attaching sandpaper to a lapping/polishing film, and then adhering the lapping/polishing film onto the polishing plate for grinding and polishing operations.

The machine is capable of processing multiple samples simultaneously, resulting in high lapping and polishing efficiency. It is well-suited for high-volume sample processing and small-batch production in factories.

Product Main Features:

1. The rotational speed is controlled manually by adjusting the frequency of the frequency inverter.

2. Double-sided lapping and polishing of up to 4 substrates with a maximum diameter of Ø2 inches can be performed simultaneously.

3. Double-sided thinning of thin wafers/sheets is achievable.

4. Ideally suited for double-sided lapping and polishing of Si, Ge, and oxide single crystal substrates.

Product Parameters

| Features | 1. Temperature and Humidity: • Relative Humidity (RH): 10-85%RH (at 25℃, non-condensing) • Temperature: 0-45℃ (32-113°F) 2. Environment: The equipment area must be free from strong vibration sources and corrosive gases. 3. Electrical Power: • Phase: Single-phase • Voltage: AC220V • Frequency: 50Hz • Socket Type: National Standard three-pole socket (China Standard) • Current Rating: 10A • Grounding: Reliable grounding is mandatory. 4. Cooling Water: • Connections: Equipped with a water inlet and outlet. • Requirement: Requires user-provided connection to tap water supply and drainage (or a recirculating water chiller/tank). 5. Air Source: Standard equipment configuration does not require an air source. 6. Optional Auxiliary Equipment: Compatible with SKZD-2/3 series Drip Feeders manufactured by our company (available for separate purchase). 7. Workbench Recommendation: • Recommended Dimensions: L800mm x W650mm x H700mm (Length x Width x Height) • Load Capacity: Minimum 150kg load-bearing capacity (330 lbs) 8. Ventilation: Good ventilation environment is sufficient; no special ventilation equipment is required. |

| Main Parameters | 1. Input Voltage: Single-phase: AC220V/ 50Hz 2. Total Power: 550W 3. Lapping/Polishing Plate Diameter: Φ240 mm 4. Lapping/Polishing Plate Speed: RMS Value: 5-65rpm (Stepless Speed Regulation) 5. Maximum Sample Diameter: Ø50mm 6. Maximum Sample Thickness: 15mm 7. Weight of Upper Lapping/Polishing Plate: 2.5kg 8. Weight of Upper Lapping/Polishing Plate Counterweight Ring: 1.3kg/1.6kg/2kg 9. Control Method: Button + Timed Operation (Countdown) |

| Product Specifications |  • Dimensions: L700mm x W550mm x H600mm • Net Weight: Approximately 80kg |

| Warranty | • One year limited warranty with lifetime support • Rusting and damage due to improper storage condition or maintenance are not covered by warranty |

STANDARD Accessories

| P/N | Item Name | Qty |

| 1 | Lapping Plate | 1 |

2 | Polishing Plate | 1 |

3 | Conditioning Ring (or Plate Conditioning Ring) | 1 |

4 | Carrier Planetary Gear (Bakelite) | 1 |

5 | Counterweight Ring | 1 |

6 | Magnetic Sheet (or Magnetic Platen) | 2 |

7 | Lapping/Polishing Film | 2 |

| 8 | Polishing Pad (Suede Leather, Synthetic Leather, Polyurethane) | 1 |

9 | Diamond Polishing Paste (W2.5) | 1 |

Optional Accessories

| P/N | Item Name | Qty |

| 1 | Custom "carrier planetary gear" molds are offered. Contact sales for your requirements. | Optional |

Office Photo

Exhibition

Contact: Bruce Liu

WhatsApp: +86-18059149998

Tel: +86-18059149998

Email: sales@supsemi.com

Add: Room 1402, Building 1, No. 89 Xibeilu, Xishancun, Xibei Street, Xinluo District, Longyan City, Fujian Province

We chat