Element Symbol:Copper (Cu)

CAS:[N/A]

Model:Sup-Cu

Purity:5N,4N,3N

Shape:Round,Square

Thickness:[N/A]

Dimension:[N/A]

(Note: Purity, shape, thickness, and dimensions can all be customized)

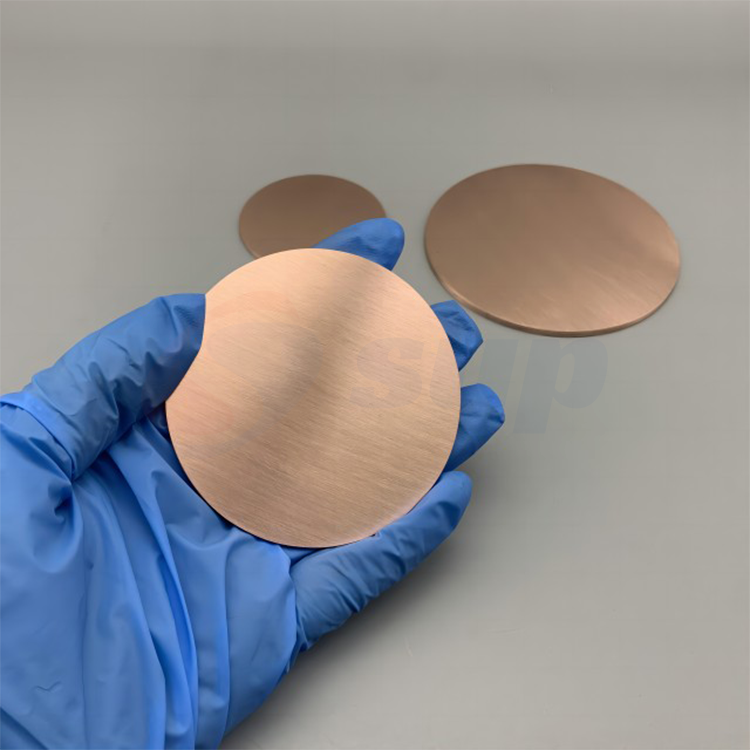

Copper (Cu) Sputtering Target Introduction

Copper (Cu) is a red metal known for its excellent electrical conductivity, thermal conductivity, and corrosion resistance. Copper sputtering targets are widely used in various industrial fields, particularly in the semiconductor, electronics, and optoelectronics industries.

Note: Purity, shape, thickness, and dimensions can all be customized,Please feel free to contact us for more details.

| Purity (%) | Shape | Manufacturing process | Max. Size |

| 99.999%, 99.995%, 99.99%, 99.7% | Plane target, Cylindrical target, Arc target, Custom-shaped target | Vacuum Melting,PM | Customized |

To receive a prompt quotation and expedited delivery, please provide complete target material specifications. This includes details on purity, dimensions, tolerance requirements, and any other technical specifications.

Main Characteristics

- Excellent Electrical Conductivity: Copper is one of the best conductive metals and is widely used for electrical interconnections and conductive materials.

- Good Thermal Conductivity: Copper has a thermal conductivity of about 401 W/m·K, making it suitable for applications that require efficient heat dissipation.

- Corrosion Resistance: Copper exhibits good corrosion resistance in various environments, especially due to the protective oxide layer that forms in air and water, effectively preventing further corrosion.

- Ease of Fabrication: Copper is easy to shape and weld, making it compatible with various manufacturing processes.

Physical and Chemical Properties of Copper

- Density: Copper has a density of about 8.96 g/cm³, providing good durability.

- Melting Point: The melting point of copper is approximately 1085 °C (1985 °F), allowing it to maintain stability under high-temperature conditions.

- Boiling Point: The boiling point of copper is about 2562 °C (4644 °F), indicating its stability in high-temperature applications.

- Reactivity: Copper is relatively unreactive and resists corrosion well, but it can react with oxygen, sulfur, and halogens under certain conditions.

- Alloy Formation: Copper can easily form alloys with other metals, such as brass (with zinc) and bronze (with tin), enhancing its mechanical properties and corrosion resistance.

Main Applications of Copper sputtering targets

- Semiconductor Manufacturing: Copper sputtering targets are used in thin film deposition processes as electrodes and conductive layers to ensure the electrical performance and stability of semiconductor devices.

- PVD Coatings: In physical vapor deposition (PVD) processes, copper sputtering targets are used to form conductive and wear-resistant films.

- Electronic Devices: Copper is widely used in circuit boards, connectors, and other electronic components to improve electrical performance.

Summary

Copper sputtering targets, with their excellent electrical and thermal properties, have broad application prospects in the semiconductor, electronics, and optoelectronics fields. Their indispensable role in modern manufacturing highlights the importance of copper as a key material in various technological advancements.

Office Photo

Exhibition

Contact: Bruce Liu

WhatsApp: +86-18059149998

Tel: +86-18059149998

Email: sales@supsemi.com

Add: Room 1402, Building 1, No. 89 Xibeilu, Xishancun, Xibei Street, Xinluo District, Longyan City, Fujian Province

We chat