Product Name: Sliding Tube Furnace (80mm OD) with Flanges for Fast Heating / Cooling

Product Model: OTF-1200X-80-SL

Product Description: OTF-1200X-80-SL is a slideable tube furnace with 3" IDx55" L Quartz tube and flanges and a maximum working temperature up to 1200°C. One pair of sliding rails is installed on the bottom of the furnace to allow sliding the furnace from one side to another to achieve max. heating and cooling rates up to 100°C/min.

Product Description

OTF-1200X-80-SL is a slideable tube furnace with 3" IDx55" L Quartz tube and flanges and a maximum working temperature up to 1200°C. One pair of sliding rails is installed on the bottom of the furnace to allow sliding the furnace from one side to another to achieve max. heating and cooling rates up to 100°C/min.

For the fastest healing, the furnace may be pre-heated to the desired temperature and then be slide to the sample's position. As for fastest cooling, the furnace can be slide to another side after sample heating is completed.

Moreover, the heating and cooling rates may reach 15°C/s under vacuum or inert gasses. This furnace provides an alternative for rapid thermal processing at the lowest cost.

Product Parameters

| Product Name | Sliding RTP Tube Furnace (80mm OD) with Flanges for Fast Heating / Cooling |

| Model | OTF-1200X-80-SL |

Furnace Structure | - Double-layer steel structure with dual air cooling fans - One pair of sliding rails are installed on the bottom of the furnace, which allows the furnace to be manually moved from side to side - Vacuum flanges and a digital vacuum gauge are installed for immediate use. - Sliding rail length is about 1200mm, the furnace can slide 600 mm distance |

Power | 2.5KW |

| Voltage | AC 208-240V Single Phase, 50/60 Hz |

| Max. Temperature | 1200°C (<1 hour) |

Continuous Temperature | 1100°C |

| Heating& Cooling Rates |

Heating Rate: 15°C/sec (RT - 150°C); 10°C/sec (150°C - 250°C); 7°C/sec (250°C - 350°C); 4°C/sec (350°C - 500°C); 3°C/sec (350°C - 550°C); 2°C/sec (550°C - 650°C); 1°C/sec (650°C - 800°C); 0.5°C/sec (800°C - 1000°C); Cooling Rate: 15°C/sec (1000 - 950°C); 10°C/sec (950°C - 900°C); 7°C/sec (900°C - 850°C); 4°C/sec (850°C - 750°C); 2°C/sec (750°C - 600°C); 1.5°C/sec (600°C - 500°C); 1°C/sec (500°C - 400°C); 0.5°C/sec (400°C - 300°C); Note: The max heating and cooling rate is achieved by pre-heat one side of processing tube to the target temperature and then slide the furnace to the other side. You may choose to place the sample in the pre-heat area or not. |

Heating Zone Length | 440mm ( single zone ) |

Constant Temperature Zone | 150mm (+/-3°C @ 1000°C) |

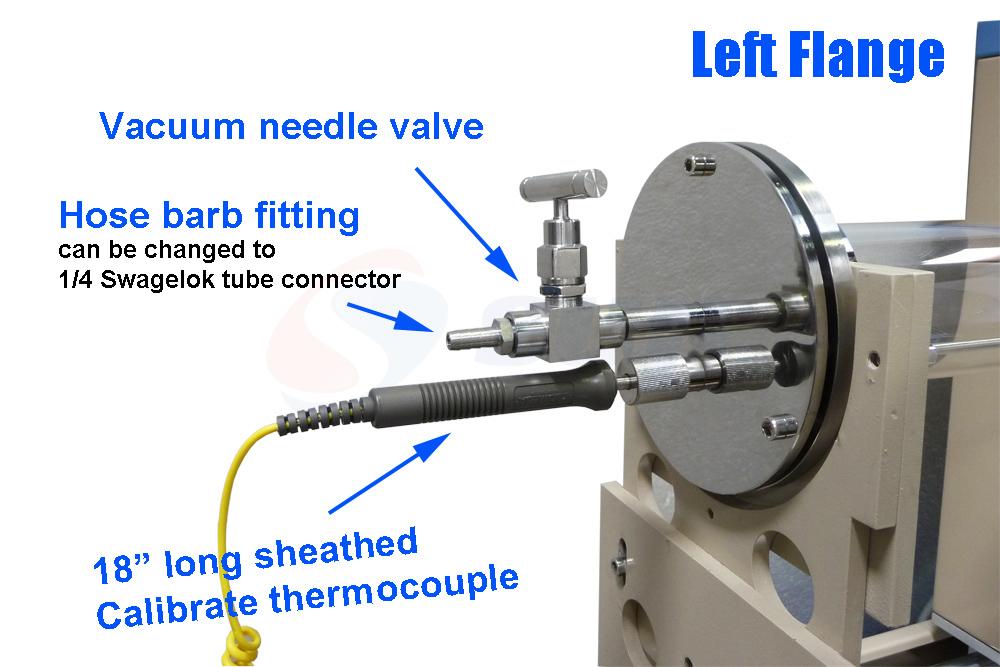

| Vacuum Flanges | Stainless steel vacuum flanges are installed on both ends of the tube with heavy duty support. Right flange: flange, fittings for the vacuum gauge are included. The bellow, KF25 adapter, KF25 clamp are not included.

Left flange: one needle valve and 1/4" thermocouple feed-through and digital vacuum gauge. An 24" length x 1/4" Dia. K-type thermocouple (included) connected to an Omega temperature calibrator (included) will be inserted through this flange to monitor the heating and cooling rates of the sample's position during furnace sliding.  |

| Sliding Rails / Table | Double sliding rail made by Cr-plated steel Sliding length: 1200 mm One slide-stopping clamp is included for holding the position of the furnace.

|

| Compliance | CE Certified NRTL or CSA certification is available upon request at extra cost. |

| Dimensions | Dimensions: 550 x 380 x 520 mm (L x W x H) ( furnace only) 1500 x 380 x 620 mm (L x W x H) ( furnace + sliding ) Weight: 102 Kg |

| Warranty | One-year limited manufacturer's warranty (Consumable parts such as processing tubes, O-rings and heating elements are not covered by the warranty, please order replacements at related products below). |

Office Photo

Exhibition

Contact: Bruce Liu

WhatsApp: +86-18059149998

Tel: +86-18059149998

Email: sales@supsemi.com

Add: Room 1402, Building 1, No. 89 Xibeilu, Xishancun, Xibei Street, Xinluo District, Longyan City, Fujian Province

We chat